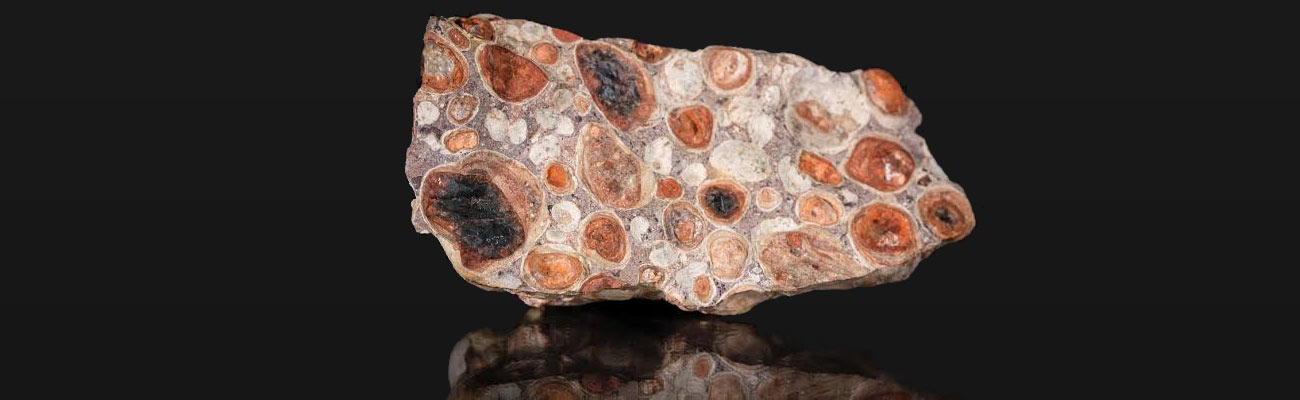

Chromite

Chromite is a mineral that is an iron chromium oxide. It has a chemical formula of FeCr2O4. It is an oxide mineral belonging to the spinel group. The element magnesium can substitute for iron in variable amounts as it forms a solid solution with magnesiochromite(MgCr2O4).

Chrome ore is one of the most usefull mineral due to its usage in production of metallic chromium, used as an alloying ingredient in stainless and tool steels. Chromite is also used as refectory material due to its high heat stability.

General Information

- Category: Oxide minerals (Spinel group)

- Formula: (Fe, Mg)Cr2O4

- Crystal system: Isometric

- Crystal class: Hexoctahedral (m3m)

Properties

It is dark gray to black in color with a metallic to submetallic luster and a high specific gravity. It occurs in basic and ultrabasic igneous rocks and in the metamorphic and sedimentary rocks that are produced when chromite-bearing rocks are altered by heat or weathering.

General Information

- Color: Black to brownish black; brown to brownish black on thin edges in transmitted light

- Crystal habit: Octahedral rare; massive to granular

- Cleavage: None, parting may develop along {111}

- Fracture: Uneven

- Tenacity: Brittle

- Mohs scale hardness: 5.5

- Luster: Submetallic

- Streak: Brown

- Diaphaneity: Translucent to opaque.

- Specific gravity: 4.5 – 4.8

Occurrences

Chromite is found as orthocumulate lenses of chromitite in peridotite from the Earth’s mantle. It also occurs in layered ultramafic intrusive rocks. In addition, it is found in metamorphic rocks such as some serpentinites. An Ore deposit of chromite form as early magmatic differentiates. It is commonly associated with olivine, magnetite, serpentine, and corundum.

Chromite is important because it is the only economic ore of chromium, an essential element for a wide variety of metal, chemical, and manufactured products. Many other minerals contain chromium, but none of them are found in deposits that can be economically mined to produce chromium.

The Manufacturing Process

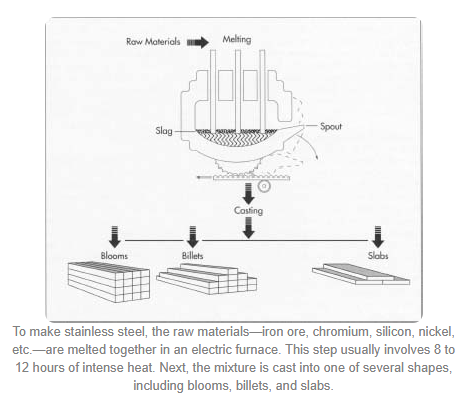

The manufacture of stainless steel involves a series of processes.

- First, the steel is melted, and then it is cast into solid form.

- After various forming steps, the steel is heat treated and then cleaned and polished to give it the desired finish.

- Next, it is packaged and sent to manufacturers, who weld and join the steel to produce the desired shapes.